Are you dealing with bore pump issues and not sure where to start? Bore pumps are a fantastic tool for accessing water, but when they break down, it can feel like a daunting task to get them running again. Whether you rely on one for irrigation, household use, or other water supply needs, knowing how to approach repairs can save you time, stress, and money.

What is a Bore Pump?

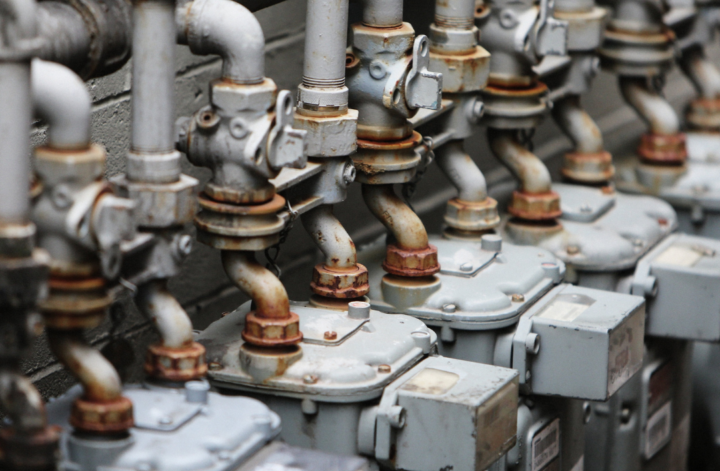

Before we dive into repairs, let’s clarify what we’re dealing with. A bore pump is a type of pump designed to draw water from underground sources, such as a borehole or a well. These pumps are typically used in rural areas or properties that aren’t connected to a centralised water system. Bore pumps are crucial for providing consistent water supply, making them an essential piece of equipment for many homes and businesses. However, like any mechanical system, bore pumps can also experience issues that may require attention. In cases of failures or leaks, it can be important to take care of the issue as soon as possible. You can consider performing basic troubleshooting and repairs yourself. However, if you feel like you might need assistance having access to professional Emergency plumber Long Beach CA, or for a place nearby, can be beneficial. They can help in taking care of the issue as swiftly as possible, and reduce further damage and disruptions this may have caused.

Common Bore Pump Problems

Bore pumps can encounter various issues, some more common than others. If your bore pump isn’t functioning correctly, you’re not alone-these are the most frequent problems people run into:

- Pump running dry – If the water level in your bore drops below the pump’s intake, it can lead to the pump running dry. This can cause severe damage, as the pump relies on water to keep cool.

- Low water pressure – This might be due to a clog in the system, a damaged pipe, or issues with the pump itself.

- Pump motor failure – Like any other machine, bore pumps can experience motor burnout, especially if they’re overworked or not maintained.

- Electrical issues – Faulty wiring or blown fuses can halt a bore pump’s operation.

- Debris clogging – Dirt, sand, and other debris can get into the pump, reducing its efficiency or causing it to stop altogether.

Diagnosing the Problem

Not sure what’s wrong with your pump? Start by troubleshooting. Sometimes, a simple fix is all it takes to get your pump up and running again. Let’s break it down:

Step 1: Check the Power Supply

Is the pump receiving electricity? Check for blown fuses, tripped circuit breakers, or faulty wiring. If the pump has lost power, resetting it might solve the problem.

Step 2: Inspect the Pump

If there’s power but the pump isn’t working, take a look at the pump itself. Is it making strange noises? Overheating? There might be internal damage, or the pump could be running dry.

Step 3: Assess the Water Supply

Low water pressure or no water at all could indicate an issue with your bore’s water levels. If the water table has dropped, you may need to adjust the pump’s position or consider upgrading to a pump that can handle lower water levels.

Step 4: Look for Clogs

Debris like sand and dirt can clog your pump and reduce its efficiency. Cleaning out the system may restore normal function.

When to Call a Professional

Sometimes, repairs are beyond DIY fixes, and you’ll need to bring in an expert for bore pump repairs Perth. But when exactly should you call in the professionals? Here are a few scenarios where it’s wise to step back and let the pros handle it:

- Motor replacement – Pump motors are complex, and replacing one involves electrical work and understanding pump mechanics.

- Bore redevelopment – If your bore is clogged with sediment or no longer yielding enough water, redevelopment might be required. This involves cleaning out the borehole and reconditioning the pump.

- Electrical issues – While you can check for power supply problems, deeper electrical issues should always be handled by a licensed electrician Houston TX (or a similar professional from where you reside).

- Persistent low pressure – If you’ve ruled out simple clogs or pipe damage and the pressure is still low, you could be dealing with a more significant issue like pump wear or underground pipe problems.

Preventative Maintenance Tips

Just like any piece of equipment, regular maintenance is the key to a long-lasting bore pump. Here are five preventative steps to keep your pump in good working condition:

- Regular inspections – Check the pump and electrical components at least once a year for any signs of wear or damage.

- Keep debris out – Install a screen or filter to prevent dirt, sand, and other debris from entering the pump.

- Monitor water levels – Ensure the water level in your bore stays above the pump’s intake to avoid running it dry.

- Lubricate moving parts – Keeping mechanical components well-lubricated will help prevent wear and tear.

- Test the pump regularly – Run the pump periodically, even if it’s not in regular use, to ensure everything stays in working order.

How to Extend Your Bore Pump’s Lifespan

Want to make sure your bore pump lasts for years to come? There are a few habits that can help:

Don’t overwork it

Only run the pump when necessary, and avoid continuous operation unless it’s designed for that.

Upgrade when needed

Sometimes, an older submersible pump simply can’t keep up. If you’re finding frequent breakdowns or insufficient water flow, it might be time for an upgrade.

Protect against the elements

Pumps that are exposed to harsh weather can wear down quicker. Make sure yours is properly housed or protected from the elements.

Final Thoughts on Bore Pump Repairs

Bore pump issues are frustrating, but they don’t have to be overwhelming. By understanding common problems, performing basic troubleshooting, and knowing when to call in the experts, you can keep your pump running smoothly and avoid costly repairs. Regular maintenance goes a long way in preventing breakdowns and extending your pump’s lifespan.